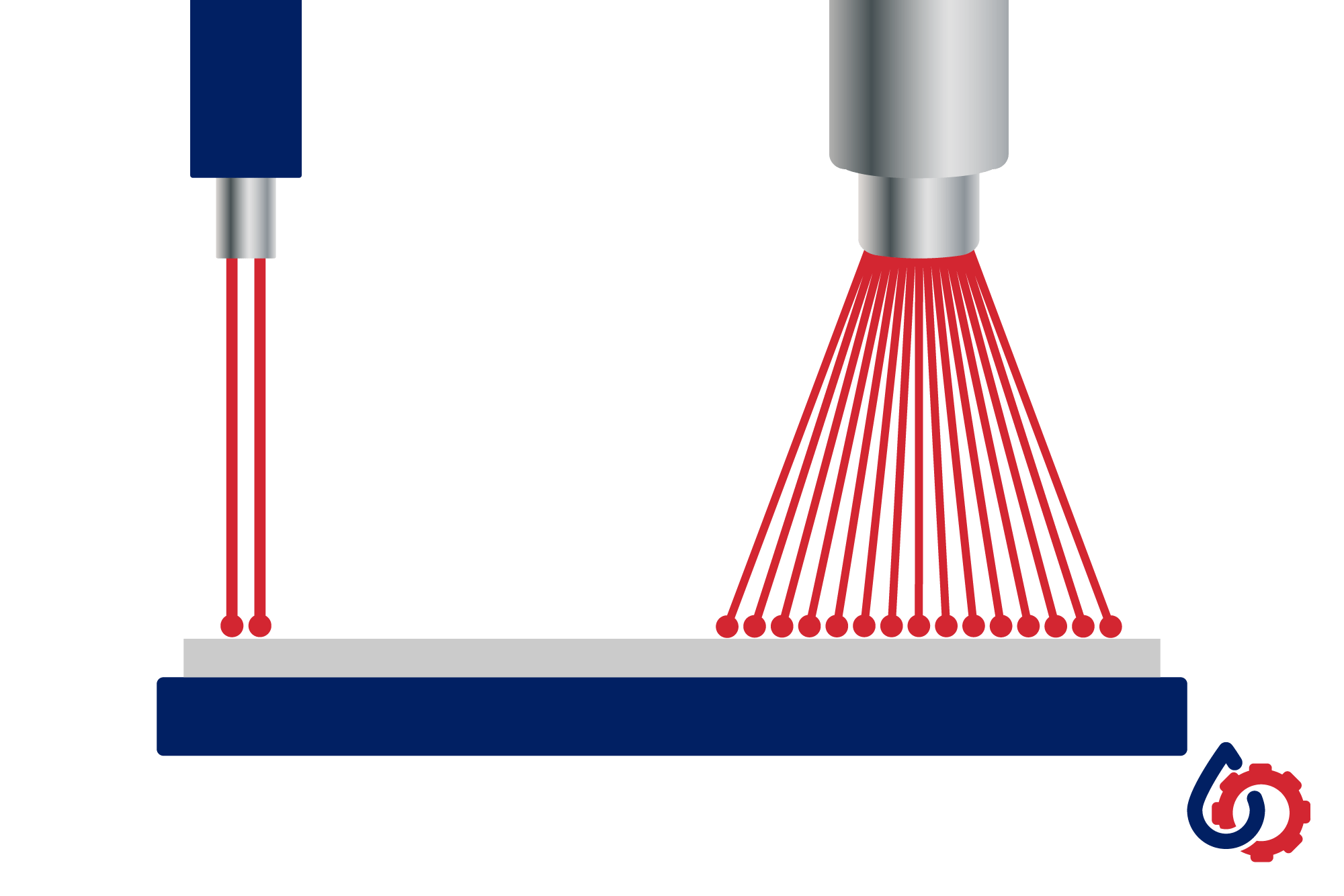

Electrostatic Oiler Styles

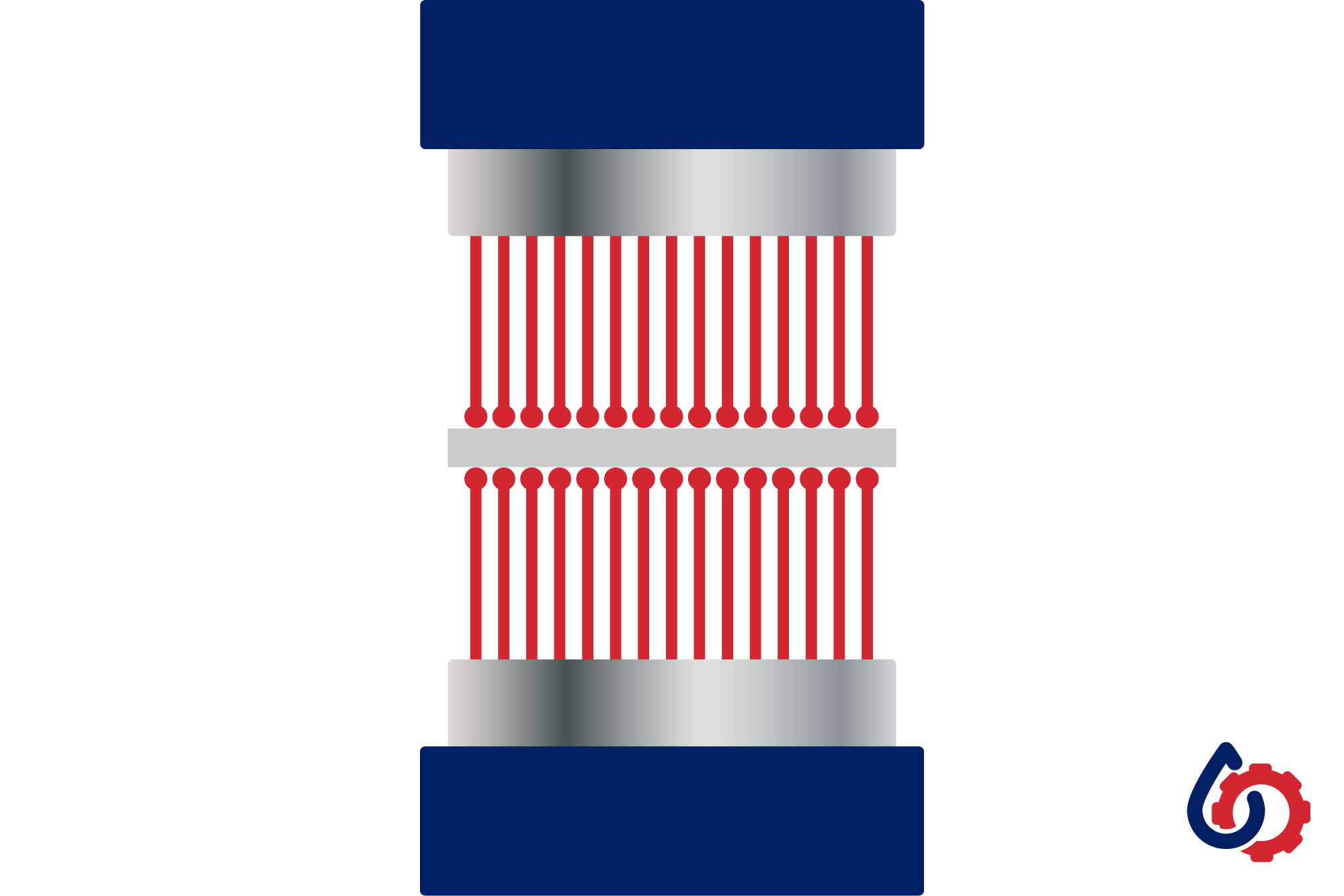

Blade

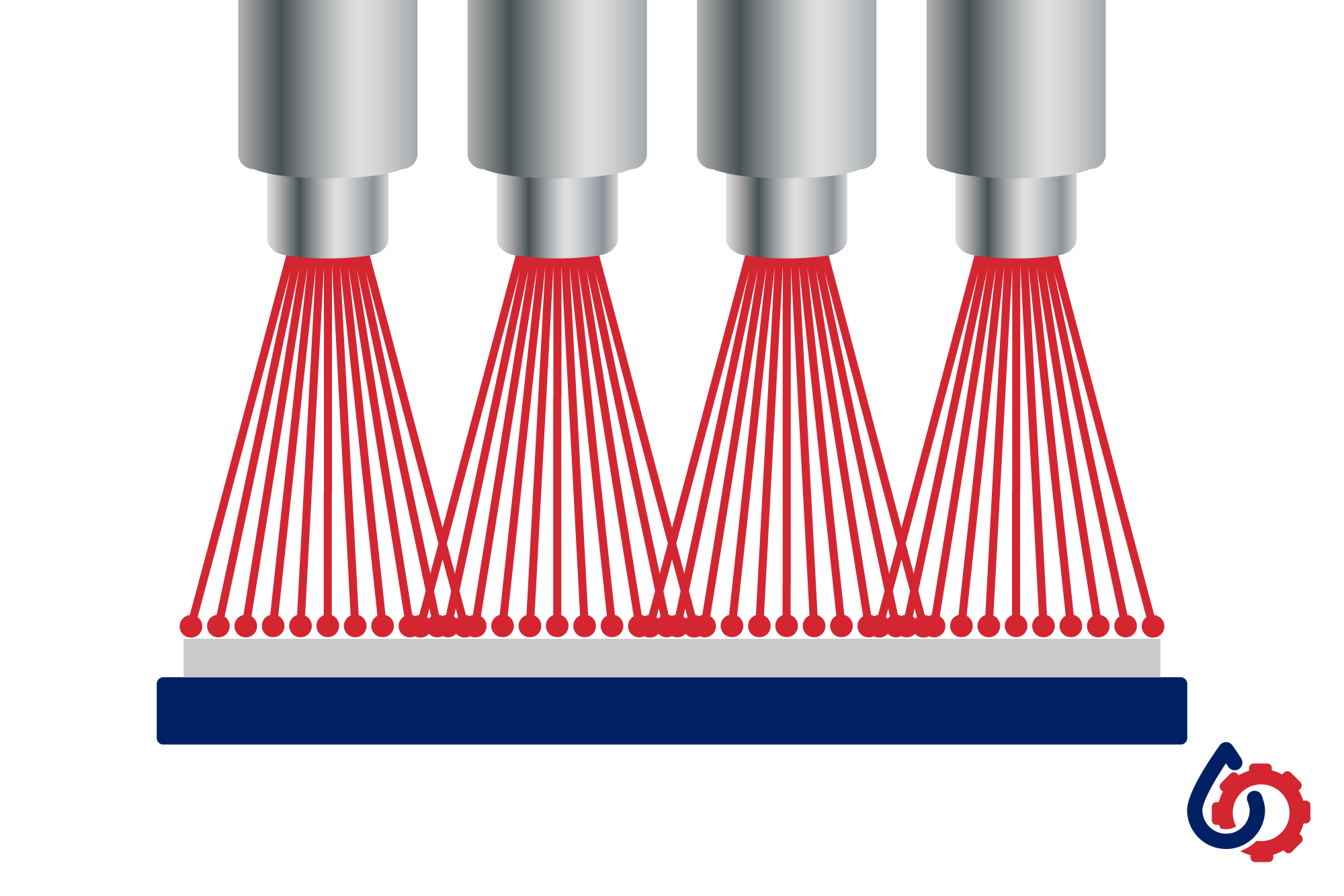

Rotary Atomizer

In Rotary Atomizer Systems, coating is delivered to a rotating bowl, then spun out to the bowl’s edge where it is subjected to an intense electrostatic energy field. The atomizer is rotated at high speeds using a friction-free air turbine. A combination of centrifugal and electrostatic energy is used to atomize and distribute coating fluids uniformly over the target surface.

Combination Blade / Rotary Atomizer Systems

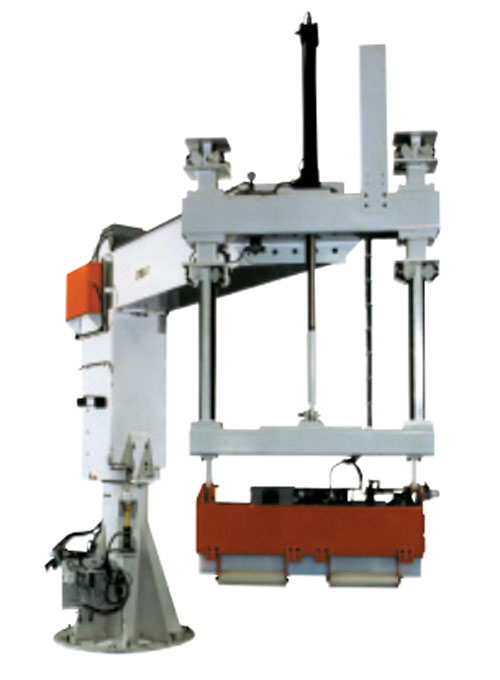

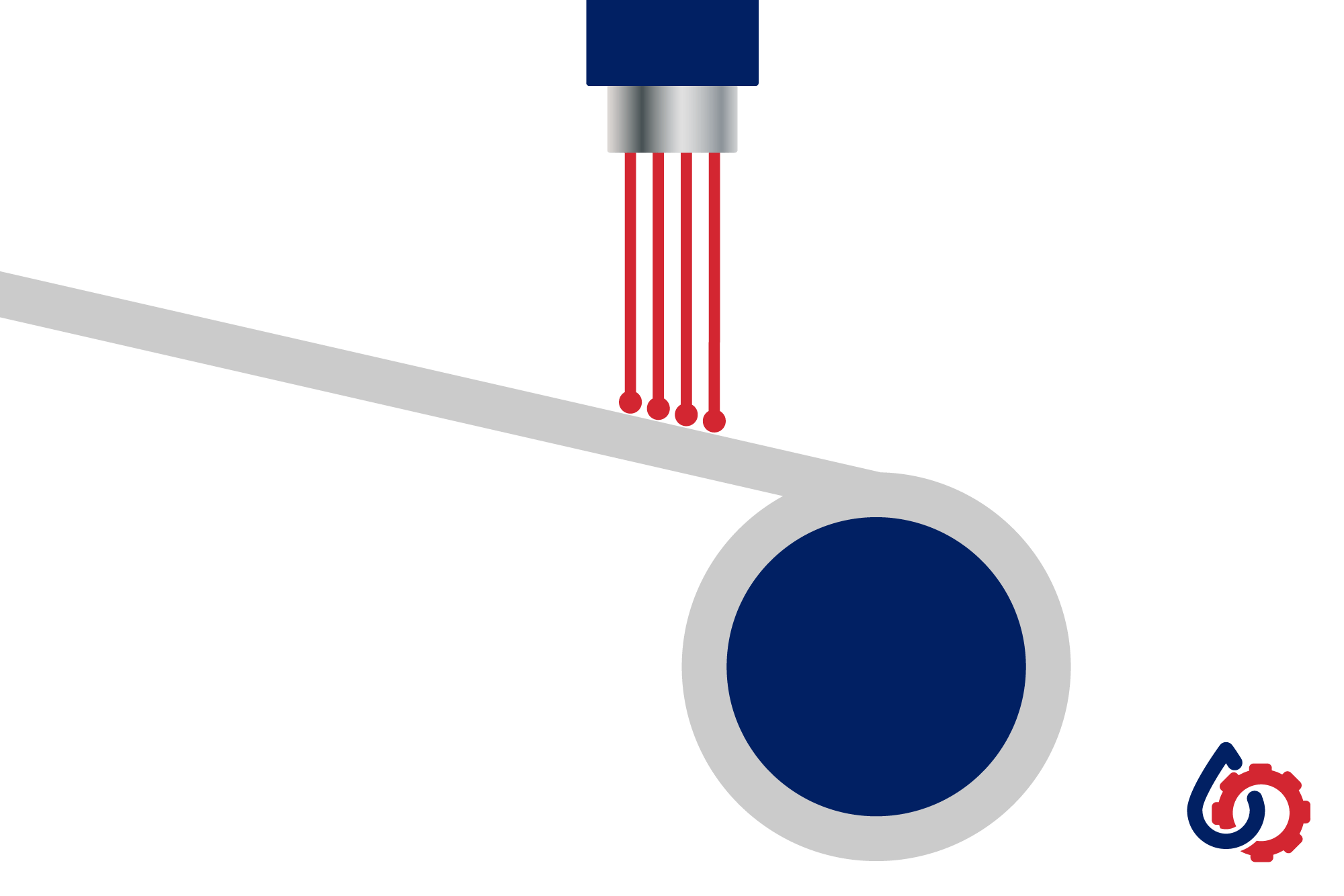

Over the Mandrel

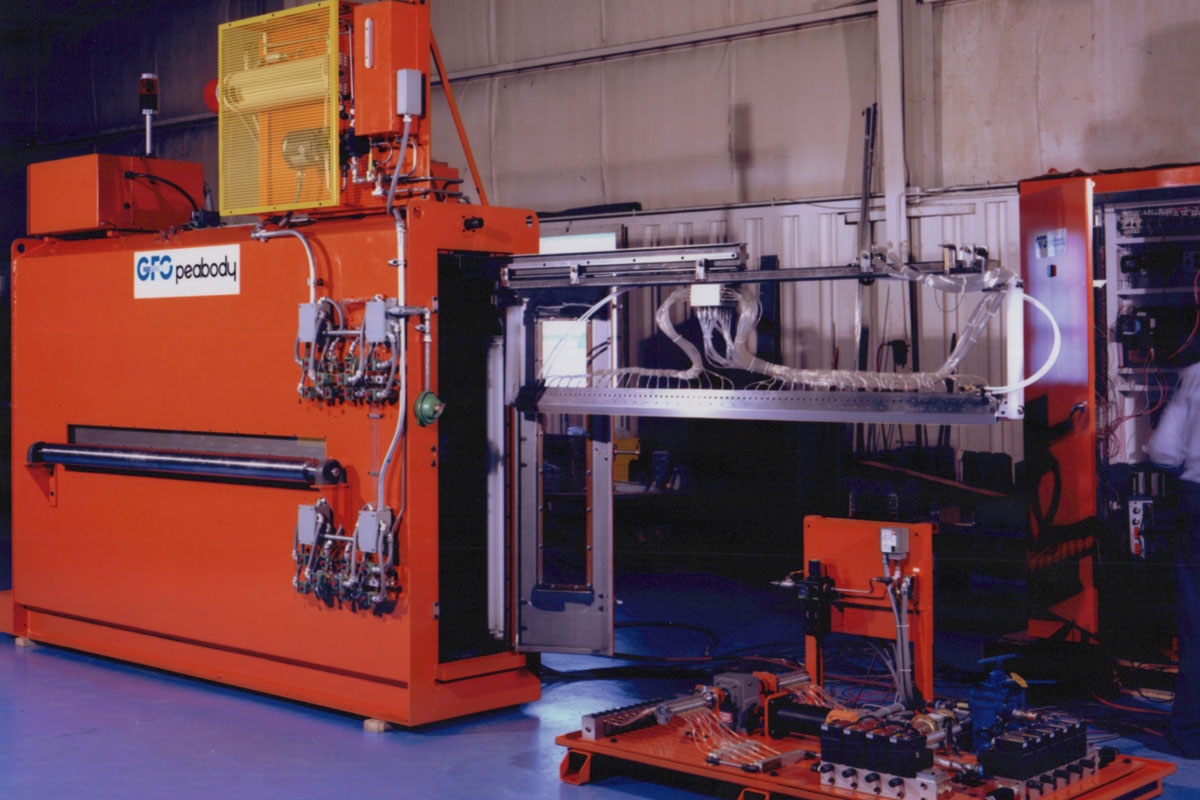

Space in a line for an enclosed oiler is not always available, as is generally the case with temper mills or skin pass mills. To address this issue, GFG Peabody has developed and successfully installed countless Over-the-Mandrel Oilers. By utilizing features such as GFG Peabody adjustable spray width blade designs, automatic height compensation software/hardware, and the patented GFG Peabody Dynamic Voltage Control, our oilers will provide you with the ultimate oiling solution when space for a conventional oiler does not exist.

Challenge us with your requirements

You will be surprised!