Custom Coil Coating Equipment

Crafted Differently

You have special needs; we are here to help. Every GFG Peabody machine is engineered to its purpose and place on your coil processing line. Built to fit and made to work. Offering an endless array of styles, features and solutions – that’s GFG Peabody. Working to give you what you didn’t get before and can’t get anywhere else. We craft our machines differently.

We don't set the industry standard. We ARE the industry standard.

What's Your Challenge?

We Can Help!

GFG Peabody is the global leader in providing revolutionary innovation in integrated, cost-effective custom coating equipment. Get ahead of technology. Stay ahead of your goals. Working to give you what you didn’t get before and can’t get anywhere else.

We craft our machines differently.

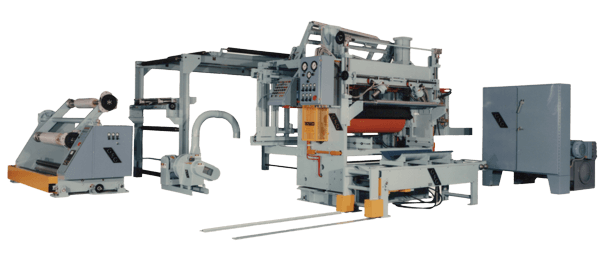

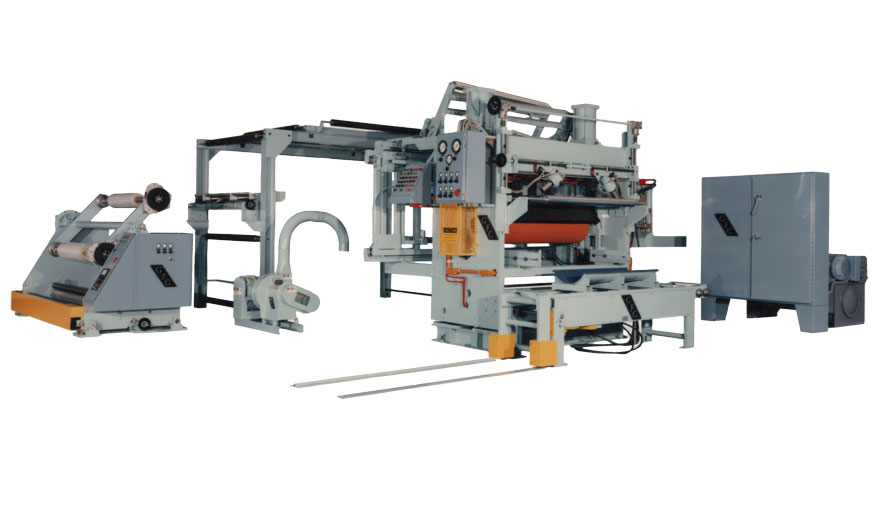

Our Equipment

Building a new coil processing line?

Ask your suppliers if they can provide GFG-Peabody equipment. We work with all coil processing line suppliers to integrate our equipment into their overall design so that you get the most innovative, safest, and top-performing coating equipment on your new line.

Highlighted Solutions

Coating Head Control System (CHCS)

The State of the Art GFG Peabody Coating Head Control System (CHCS) significantly improves control of your coating heads.

CHCS was specifically designed to meet the needs of coil coaters whose high process speed, stringent quality control specifications and/or numerous coater set-ups demand something better than manual adjustments. CHCS can reduce waste, improve consistency and the accuracy of application. Standard gearbox head adjustments are replaced with high-speed servo-controlled roll positioning allowing for greater accuracy, faster and repeatable coater setups, and continuous feedback and monitoring of the coater.

RAINBOW - A New Paradigm for industrial color measurement

Break free from color measurement limitations with Rainbow. Capture real-time data. Combining exceptional accuracy with unparalleled speed, Rainbow sets a new standard in color measurement.

Rainbow sets the standard in high-quality production control, ensuring precision at every step. Streamlining processes, Rainbow empowers seamless and precise operations for unparalleled productivity.

Arrange a video demonstration experience the innovation and precision for yourself.

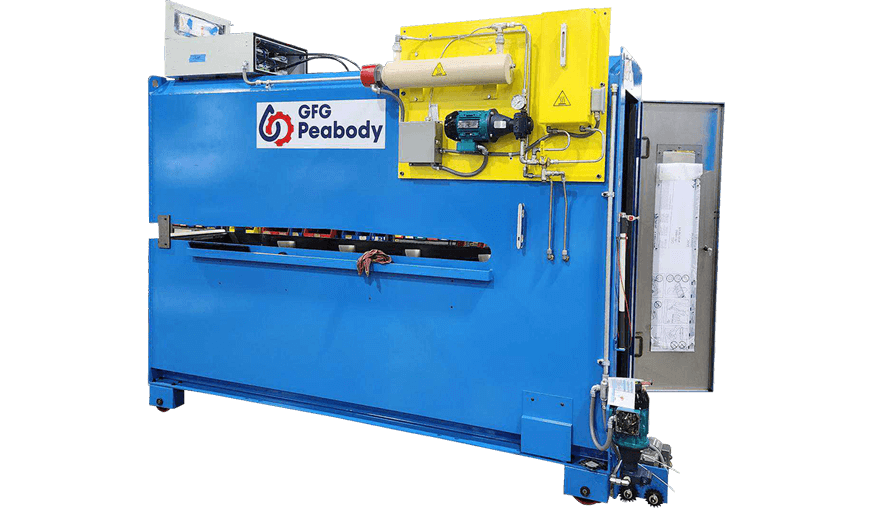

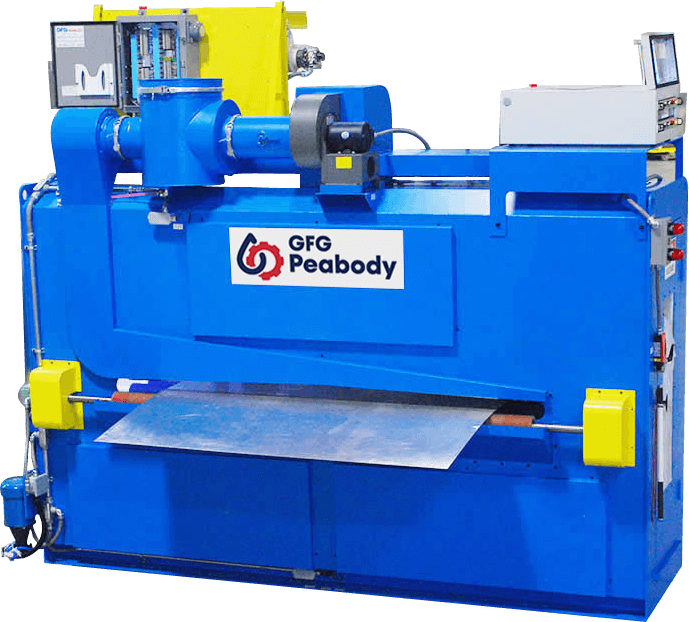

Electrostatic Dry Film Lubricant (Wax) Coating

When a metallic strip needs a unform and light application of wax to the top and bottom, for the purpose of drawing lubrication, GFG Peabody offers a dry film lubricant electrostatic oiler.

Electrostatic forces are used to apply the wax so that no air or fluid pressures than can cause overspray, uncoated patches, or waste. The wax is stored and transported by special equipment specifically engineered for your application. Variable levels of wax can be applied based on recipe with incredible precision.

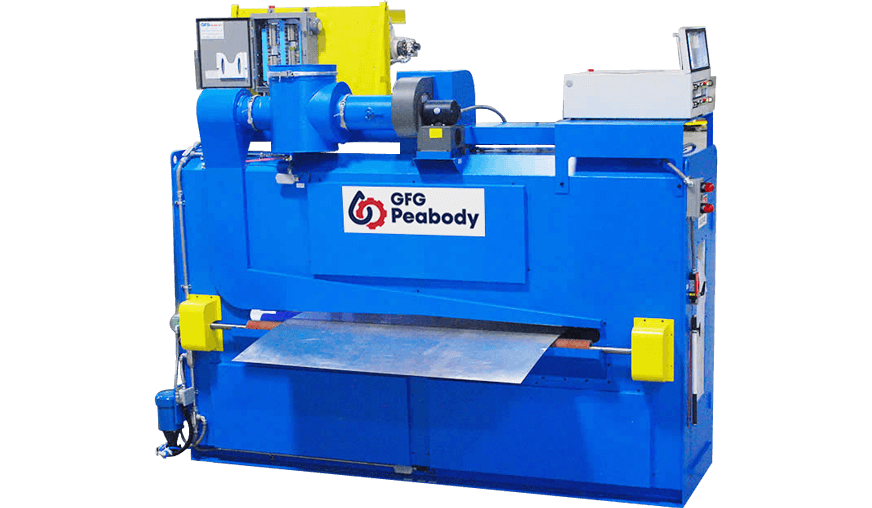

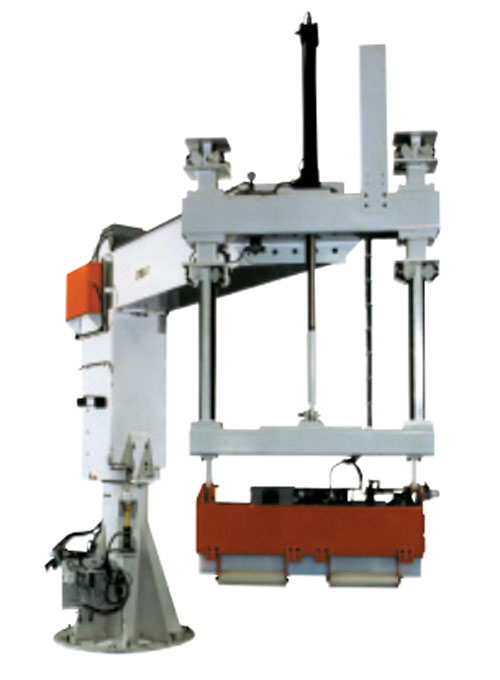

Over the Mandrel Oilers

Space in a line for an Electrostatic Oiler is not always available, as is generally the case with temper mill, skin pass mill and similar lines. To address this issue, Peabody has developed and successfully installed countless “Temper Mill or Over-the-Mandrel” Oilers.

By utilizing features such as GFG-Peabody adjustable spray width blade designs, automatic height compensation software/hardware, and the patented GFG Peabody Dynamic Voltage Control, our oilers will provide you with the ultimate oiling solution when space for a conventional oiler does not exist.

Contact Us

Let us know how we can help! Contact us online or give us a call at 262-372-4515.